Tesla major structural repair demands advanced skills due to unique EV materials, design, and integrated systems. It involves safe disassembly and reassembly of high-strength alloys and composites while preserving electrical and software functionality. Choosing a collision center with expertise in these complex repairs ensures optimal outcomes for top-tier service that maintains performance, safety, and advanced driving capabilities. Services like tire and auto detailing complement the process, aiming to restore structural integrity, aesthetics, and reliability for Tesla owners.

In the realm of automotive care, Tesla major structural repairs stand out as intricate procedures demanding certified expertise. Electric vehicles (EVs) present unique challenges due to their advanced design and materials, necessitating a deep understanding for accurate diagnostics and safe repairs. This article delves into the complexities of Tesla major structural repair, highlighting why certified professionals are indispensable. By exploring specialized knowledge, advanced tools, and industry insights, we uncover the benefits of engaging experts, ensuring precision, warranty protection, and vehicle value preservation.

- Understanding Tesla Major Structural Repair: The Complexities Involved

- – Definition and scope of major structural repair for Tesla vehicles

- – Unique challenges posed by electric vehicle (EV) design and materials

Understanding Tesla Major Structural Repair: The Complexities Involved

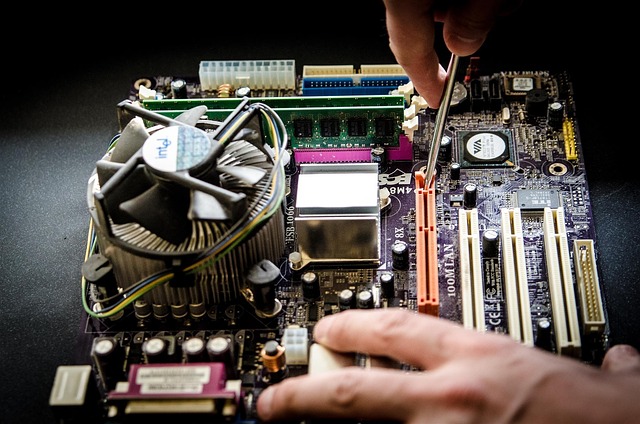

Tesla major structural repair is a specialized service that requires an in-depth understanding of the vehicle’s intricate design and advanced materials. Unlike conventional auto collision repair or even basic auto detailing, this process involves meticulous attention to detail and precise technical skills. The complexities stem from Tesla’s innovative use of lightweight, high-strength materials like aluminum alloys and composite structures, which demand specialized tools and techniques for safe disassembly and reassembly without compromising structural integrity.

A certified expertise in Tesla major structural repair encompasses not just the physical aspects but also a deep knowledge of the vehicle’s electrical and software systems, as many components are integrated into the chassis. This ensures that any repairs or modifications are performed accurately, preserving the original performance, safety standards, and advanced driving capabilities associated with Tesla vehicles. Choosing a collision center with proven experience in handling such complex repairs is crucial to ensure optimal outcomes for owners seeking top-tier service.

– Definition and scope of major structural repair for Tesla vehicles

Major structural repair for Tesla vehicles refers to extensive renovations that address critical components of a car’s frame and exterior. This can encompass everything from replacing damaged panels and fenders to realigning bent frames, ensuring the vehicle maintains its structural integrity and safety standards. The scope includes both aesthetic improvements and functional repairs, aiming to restore the car to its original condition or even enhance it with modern design elements while adhering to Tesla’s high-quality manufacturing guidelines.

Tesla vehicles, renowned for their advanced technology and sleek design, demand specialized attention when undergoing major structural repair. Unlike conventional cars, electric vehicle (EV) components necessitate careful consideration due to battery placement and unique body paneling. Certified experts in auto body restoration, proficient in handling both standard and EV-specific challenges, are crucial for accurate measurements, precise cutting, and seamless welding, thereby guaranteeing not just the visual appeal of a restored Tesla but also its long-term performance, safety, and reliability. Complementary services like tire services and auto detailing can further enhance the overall quality of the repair, ensuring customers receive a vehicle that meets their high expectations.

– Unique challenges posed by electric vehicle (EV) design and materials

Tesla major structural repairs present unique challenges due to the distinct design and materials employed in their electric vehicles (EVs). Unlike traditional internal combustion engine cars, EVs have lightweight yet sturdy structures designed for optimal energy efficiency and range. This requires specialized knowledge when it comes to repairing significant damage, such as frame bends or panel replacements. The use of advanced materials like high-strength steels and composite fibers adds another layer of complexity. These materials demand precise handling and specific repair techniques to maintain structural integrity without compromising the vehicle’s performance and safety features.

Furthermore, the intricate electrical systems and battery packs integrated into Tesla EVs necessitate careful consideration during any major repair process. Unlike conventional cars, a simple bumper repair or car dent repair in an EV might involve delicate operations near sensitive components. Certified technicians are trained to address these challenges, ensuring that repairs not only restore the vehicle’s aesthetic appeal but also preserve its technological capabilities and overall functionality.

Tesla major structural repair is not a task to be taken lightly. Due to the complex design and innovative materials used in EV construction, specialized knowledge and certified expertise are paramount to ensure proper repairs that maintain the safety, performance, and longevity of these vehicles. By adhering to strict standards and employing advanced techniques, certified technicians can accurately address major structural issues, preserving the value and reliability of Tesla cars for years to come. This specialized care is essential for maintaining the reputation and integrity of both Tesla as a brand and the EV ownership experience.