Tesla major structural repair involves meticulous welding and adhesive bonding techniques to restore critical components, maintaining safety and integrity. Skilled technicians use precise methods to replicate original structures and achieve seamless finishes, addressing from tire services to complex parts. Adhesive bonding, a game-changer, offers powerful and flexible repairs for intricate areas, enhancing durability and aesthetics without damaging surrounding components.

Tesla major structural repairs demand precision and expertise. Whether it’s a collision or routine reinforcement, understanding the process is key. This article delves into the intricacies of these repairs, focusing on two primary techniques: welding for metal integrity and adhesive bonding for enhanced strength. By exploring these advanced methods, we highlight how Tesla ensures the safety and longevity of its vehicles, providing valuable insights for both enthusiasts and industry professionals interested in Tesla major structural repair.

- Understanding Tesla Major Structural Repairs

- The Role of Welding in Repair Process

- Adhesive Bonding: A Key Technique for Strengthening

Understanding Tesla Major Structural Repairs

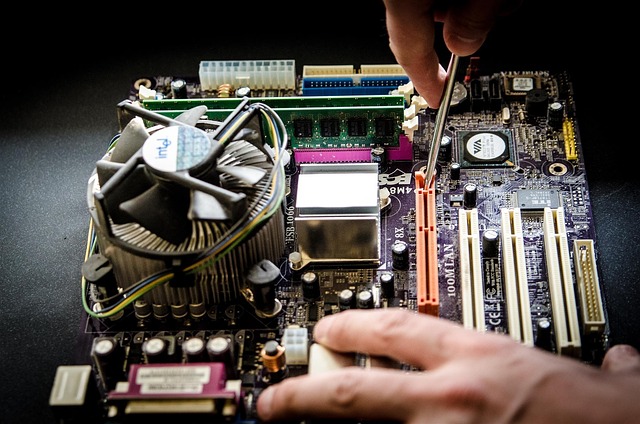

Tesla major structural repairs are a specialized process that involves meticulous welding and adhesive bonding techniques to restore critical car components. These repairs cater to significant damages, ensuring the vehicle’s safety and structural integrity. When a Tesla, known for its advanced technology and sleek design, undergoes such repairs, it demands precise handling due to intricate mechanical systems.

Automotive repair services for Tesla focus on both functional and aesthetic restoration. Car body restoration techniques, including welding, are employed to fix broken or damaged panels, frames, and other major structural elements. Adhesive bonding adds a layer of sophistication by providing a strong, long-lasting bond, often used in conjunction with high-quality adhesives designed for automotive applications. This comprehensive approach guarantees not just a visually appealing car body restoration but also ensures the vehicle’s overall safety and performance, addressing various issues from tire services to intricate structural components.

The Role of Welding in Repair Process

In the intricate process of Tesla major structural repair, welding plays a pivotal role. It serves as the foundation for restoring the car’s integrity, ensuring that every component is securely in place. Skilled technicians meticulously employ this technique to join metal parts, creating robust bonds that mimic the original structure. This expertise is crucial, especially given the high-precision requirements of Tesla vehicles.

Beyond welding, adhesive bonding is another key strategy employed in these advanced vehicle repair services. It offers a unique advantage in terms of both strength and flexibility, allowing for precise adjustments during the car collision repair process. Adhesives used in car paint services are meticulously chosen to match the original material, providing a seamless finish that was once thought impossible to achieve through traditional methods. This combination of welding and adhesive bonding redefines the standards of Tesla major structural repair, ensuring not just functionality but also aesthetics that rival the manufacturer’s original craftsmanship.

Adhesive Bonding: A Key Technique for Strengthening

Adhesive bonding is a critical technique in Tesla major structural repairs, offering a powerful solution for enhancing vehicle durability and aesthetics. This method involves applying specialized adhesives to join various components together, creating a strong and long-lasting bond. In contrast to traditional welding techniques, adhesive bonding allows for the repair of intricate and delicate areas without causing damage or stress to surrounding structures.

For auto body services focusing on hail damage repair, adhesive bonding is particularly valuable. It can effectively restore vehicles to their original condition by seamlessly integrating new parts with existing panels, ensuring both structural integrity and a seamless finish. This advanced technique complements traditional body shop services, providing customers with top-notch repairs that match the vehicle’s initial quality.

Tesla major structural repairs demand advanced techniques like welding and adhesive bonding. These methods ensure strength, precision, and longevity in restoring vehicles to their optimal condition. By leveraging these innovative strategies, professionals can effectively address complex repairs, underscoring the importance of both traditional and modern approaches in the automotive industry.